World Population Count

Human-generated waste is a worldwide problem with most current solutions only adding to environmental damage. The United States alone generates roughly 268 million tons of waste per year. Current recycling programs only address 32.1 percent of the total waste. As the world population grows and consumption increases, waste will increase proportionally as well. Landfills and other current methods for handling waste will only contribute to wastewater contamination and other anthropogenic causes of environmental crisis.

Anthropogenic environmental damage can be halted with the latest technology from Pyrogen Energy. Aside from the environmentally friendly operation, a Pyrogen Energy system also generates revenue through electricity production. Amazing opportunity exists for countries and businesses all over the world to both eliminate waste in an environmentally responsible way and generate revenue by reducing the need to burn fossil fuels to generate electricity.

Enormous benefits can be realized with our system, including self sufficiency in a closed loop. This system is the only system of its kind currently available. Using patents we currently hold as well as patent-pending technology, Pyrogen Energy leverages an enhanced plasma arc to process virtually any carbonaceous waste to drive high-efficiency turbines, creating an electric surplus. The electricity can be grid-tied and sold directly to the utility provider.

Plasma Arc Gasification

Plasma arcs have been used for years to treat waste products and incinerator ash, converting them to a non-hazardous, glassy slag. Only recently, plasma arcs have been used to process MSW (Municipal Solid Waste).

Plasma arc uses an electric current that passes through a gas (air) to create plasma which gasifies waste into syngas. This typically occurs in the range of 4000°C to 6000°C. As with conventional gasification, the syngas produced can be for power generation, heating, or as a chemical feedstock. Due to the high temperatures and throughput capability, these systems have the potential to produce up to 2,400 net kWh/ ton of processed feedstock. There is tremendous potential to convert MSW to electricity more efficiently than conventional pyrolysis and gasification systems due to high heat density, high temperature, the almost complete conversion of carbon-based materials to syngas, and conversion of inorganic materials to a glassy, non-hazardous slag.

Pyrogen Energy utilizes a patent-pending induced electric arc gasification chamber to process any material, such as MSW, yard trimmings, food scraps, excess biomass from farms and forests, non-recyclable paper products, and wood debris from construction. This process creates a large amount of steam heat, which can be used to generate electricity, heat or cool nearby buildings, or to warm a greenhouse or agricultural operation. The process also creates a large amount of medium BTU gas which can be used to create additional electricity or even liquid fuels, such as bio-diesel or jet bio-fuel. Virtually any type of carbonaceous waste can be used as feed stock. Material is first shredded then fed into the reactor using a sealed hydraulic piston- or screw-feed system.

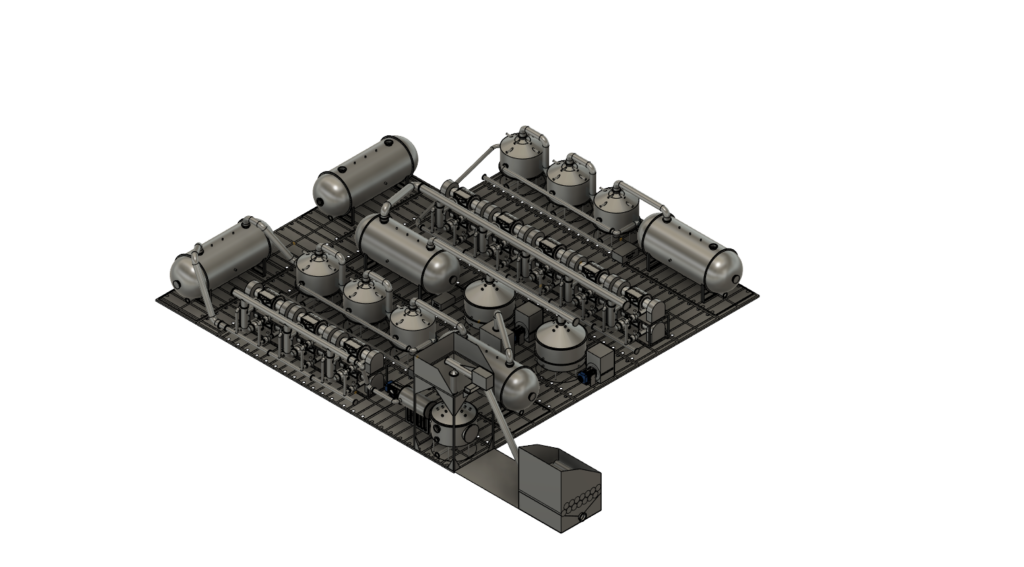

Pyrogen Energy Systems

One Pyrogen System 10 TPH (Ton Per Hour) – 10 tons Per Hour (14 MWE) 240 TPD (Tons Per Day) 336 MWE / per day System

Processing capability of any of the following:

- Municipal Solid Waste

- Agricultural Waste

- Paper Mill Sludge

- Auto Fluff

- Petroleum Coke

- Medical Waste

- Refuse Derived Fuel

- Coal

- Rice Straw

- Sewage Sludge

- Rubber Tires

- PCBs

- Wood Waste

- Hazardous Waste

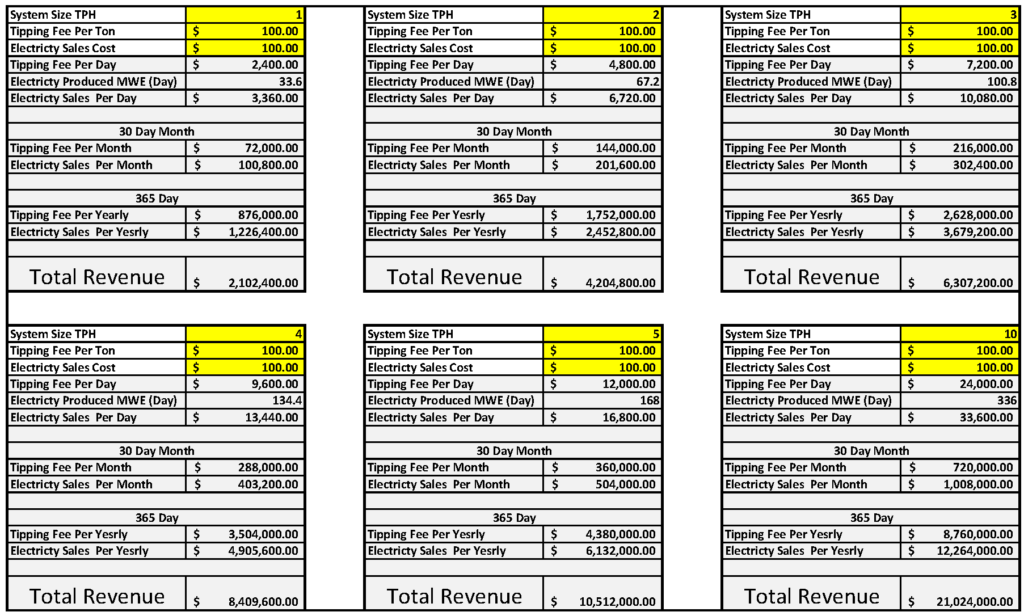

Example of return:

(T) Tipping Fees Paid to take trash / MSW / waste stream ($100.00 Per ton)

(E) Fee for sale of electricity sold ($100.00 Per Mega-Watt) (1000 KWH) 10 tons per hour * (E) * (T) = $2400.00 Per Hour / Per 10 tons

24 Hours = $57,600.00

1 Month (30 Days) = $1,728,000.00

1 Year (365 Days) = $21,024,000.00